Description

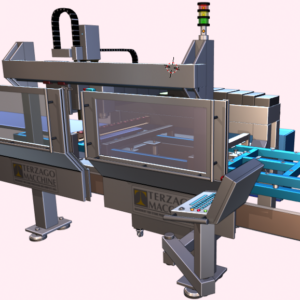

EASY 725 SUPER 5 AXIS Saw

– Machine with compact dimensions, specially made for laboratories with space problems, for the production of worked like: shaped pieces, shaping with horizontal blade, plans shower, plans kitchen of average and great dimensions, several contornature both in marble than granite.

Its main characteristics are:

– Slide of disc-holder slips on guides in hardened steel, cold-drawn, in class of precision H and sliding-block with recirculating balls pre-loaded for the elimination of the mechanical clearance

– Positioning with pinion- helical rack system of precision and epicycle reducer with 0 clearance (Axis X)

– Sliding of the bridge on guides in hardened steel, cold-drawn, in class of precision H and sliding-block with recirculating balls pre-loaded

– Positioning with 2 motors in electrical-axis with pinion- helical rack system of precision and epicycle reducers with 0 clearance (Axis Y)

– Sliding of head-holder on over-dimensioned chromed cylinder.

– Positioning with system screw-nut with recirculating balls pre-loaded and epicycle reducer with 0 clearance (Axis Z)

– Spin of the head with reducer of high precision with eccentrics with 0 clearance (Axis C) 360°

– Spin of the mandrel 0°-90° reducer of high precision with eccentrics with 0 clearance (Axis A)

– All the drives complete with elevated inertia BRUSHLESS motors, digitally controlled with system CAN-BUS

– Motor of the blade directly connected to the disc, rated power 15Kw (S6)

– Possibility of tilted cut in small steps obtained with interpolation of the axis horizontal and vertical.

– Switchboard with isolation IP 55 at the right of the machine and outside of the foundation wall, with the general switch and block door. In the control panel are grouped the contactors with the relative thermal protections, the drives and the electronics controls, the complete CNC control while the Touch screen panel and the keyboard are positioned in a remote pendant box.

– Laser beam facilitates positioning of blade on cutting line.

– Water pressure switches stops machine, if cooling water insufficient

– Tools are protected by an electronic ammeter to prevent use above preset values

– Refrigeration pipes and electrical wiring protected in plastic cable trailer chain.

MAIN FEATURES OF CNC CONTROL

– CNC Numerically controlled programmer for the management of 5 axes (X-Y-Z-A disc inclination and C head rotation),

Y Bridge translation

X Right-left translation of the head slide

Z Up-Down movement of the mandrel

A Mandrel inclination 0° -90°

C Head rotation 360°

– Control of the horizontal and vertical cutting movement of the disc head, of the bridge translation and of the rotation of the head

– Complete control of the inclination of the disc motor.

– Cutting programs in single step for marble or multiple steps, with small increments programmable, for granite

– Auto teach-in and electronically set of the end-stroke cutting and return on the slide of the disc head

– Auto teach-in and electronically set of the end-stroke for the bridge translation

– Setting of the cut-return with different values on the cut and return and last cut.

– Programming of circle or curve cutting cycles, diagonal or orthogonal cuts by interpolation of Y-X and C axes

– Positioning of the machine with all the axes moving at the same time, reducing waste time

– Execution of the finishing cycle with the side of the blade (brushing system obtained with interpolation of Z-Y axes and steps of X axes)

– Execution of excavation cycles both in roughing and finishing, concave and convex obtained with interpolation of X-Z axes with steps of Y)

– Completely automated cycles permit the execution of all the programs without the presence of the worker

– MACRO programs for the execution of shaping with the disc, contouring and excavation with discs

– Programming on the touch screen on-board of the machine or on a remote computer with CAD software, DXF files loadable created on 12 or newer editions.

– CNC control ready to use camera image acquisition system to load SLABS pictures and create cutting programs

– CNC control ready to use TELESERVICE, it is necessary to have a Ethernet Cable and an INTERNET connection (not supplied)